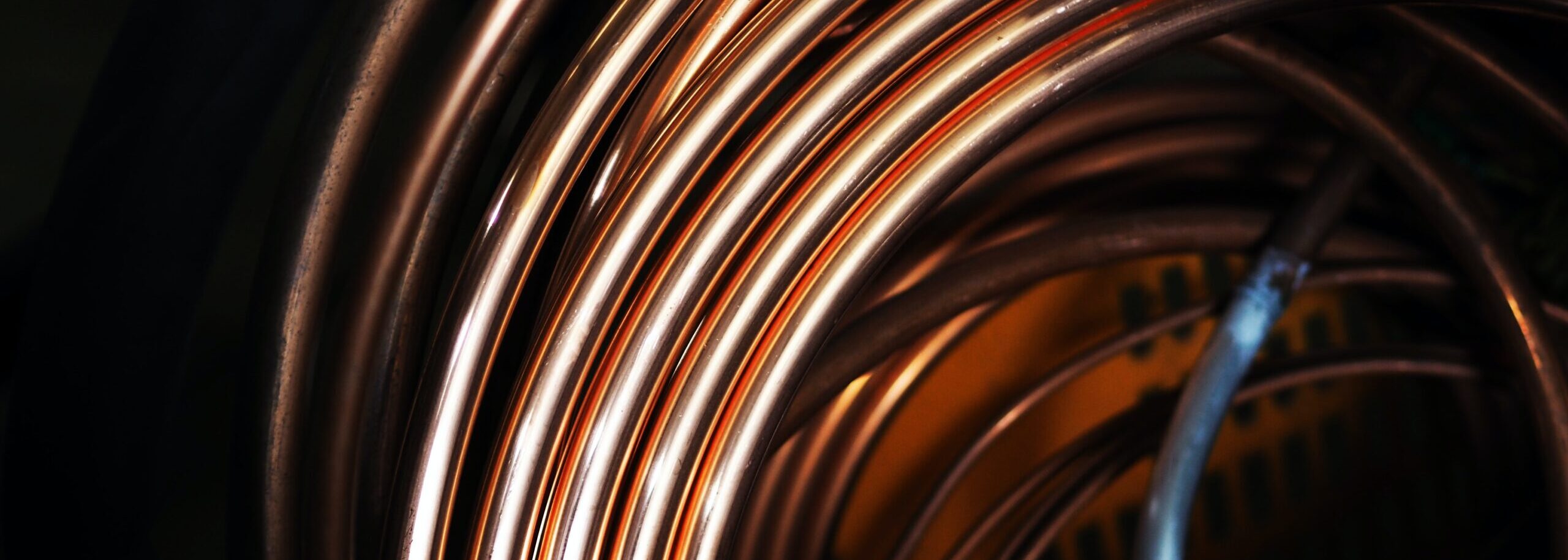

Recycling of Copper is one of the most important base metals and an important economic factor. The copper industry is of great economic and social importance. Since there are hardly any copper deposits of its own in Germany, almost half of the copper is obtained by recycling. In this way, the copper producing and processing companies make an important contribution to climate protection and make a significant contribution to a functioning, closed and sustainable circular economy.

In the course we will tell you the advantages of copper recycling

Saving resources thanks to recycling

Recycling saves resources, reduces the environmental impact and achieves energy savings, as the energy requirement for the process steps of mining, processing and smelting is eliminated. Copper is the material that is probably most often reused all over the world. For generations, the collection and trade of scrap and scrap materials for copper and copper alloys has been well organized. The reason is the excellent suitability of the copper materials for reuse

Copper recycling offers consistent quality

In addition to energy savings, the quality to be achieved during recycling is decisive for the evaluation of the production of metals from return materials and scrap. If this is not achieved, then the advantages in terms of energy savings are questionable, since the energy requirements of dissimilar materials are compared. For example, in contrast to copper in some other metals and plastics, it is not easily possible to produce products with the same quality as made of new metals. In the case of copper, on the other hand, it is possible to produce products without loss of quality that do not differ in any way from those made of primary metals. The decisive advantage in the recycling of copper materials lies precisely in the fact that copper does not suffer any quality losses even with repeated recycling, regardless of whether metallic or non-metallic, low-copper or high-copper feedstocks are reused.

The classic recycling rate is calculated from the amount produced per year from secondary materials in relation to the annual production. For copper, according to this definition, there is a reuse rate of about 50%. However, this figure says little about the reuse of a material. This is because the definition does not take into account that old material comes from durable goods that were produced at a time when the annual copper production was significantly lower. And when calculating the reuse rate, the secondary copper production is related to the much higher production today. This classic recycling rate is misleading in that it does not express the true degree of reuse of scrap materials of the material copper.

Recycling saves resources

Meanwhile, rd. 50% of the copper used in Europe is recycled. In Germany, more than 45% of the copper produced in this country comes from recycled material. This is a record and makes it clear that the current copper demand is increasingly being met from recycling. This “win-win” situation helps to meet the ever-growing demand for this metal, while at the same time reducing the environmental impact associated with copper production. In addition, increased recycling will additionally ensure copper availability for future generations.

The recycling of copper is a very effective way to return the valuable material back into the production cycle. In fact, copper production from secondary materials requires only a maximum of 20 percent of the energy required for the extraction of primary copper from ore and concentrates. Globally, this saves 100 million MWh of electrical energy and reduces Co2 emissions by 40 million tons per year. In principle, copper can be recycled again and again in its applications without any loss of quality.

Almost all copper products can be recycled

Copper is mainly used in construction, vehicle construction and electrical engineering. About 20 kg of copper are contained in a conventional passenger car, and about 75 kg of copper are installed in an electric car. Almost all copper-containing materials from products of all areas of application can be used for recycling. The primary materials used are, for example, production scrap (sheets, stamping waste, wires, pipes), old copper (old pipes, gutters, roof covers, copper cables), alloy scrap (fittings, door handles, ship screws made of copper alloys), electronic scrap, production residues and shredder material (e.g. mobile phones and computers)

I like that you mentioned how one effective way to return valuable material back into the production cycle is by recycling copper. We have some scrap copper in our storage shed and I think we should get rid of them now. Instead of putting them in the garbage can, I think it would be better to take them to a copper recycling establishment.

Saving as many resources as possible by recycling things like copper and other materials could indeed be quite important. We have a lot of unused appliances here that I can expect are made of materials like copper and other kinds of things we can send to plants. I’ll take this into account and look for a copper recycling expert as soon as possible so they can lend us a hand with processing these kinds of items for sure.